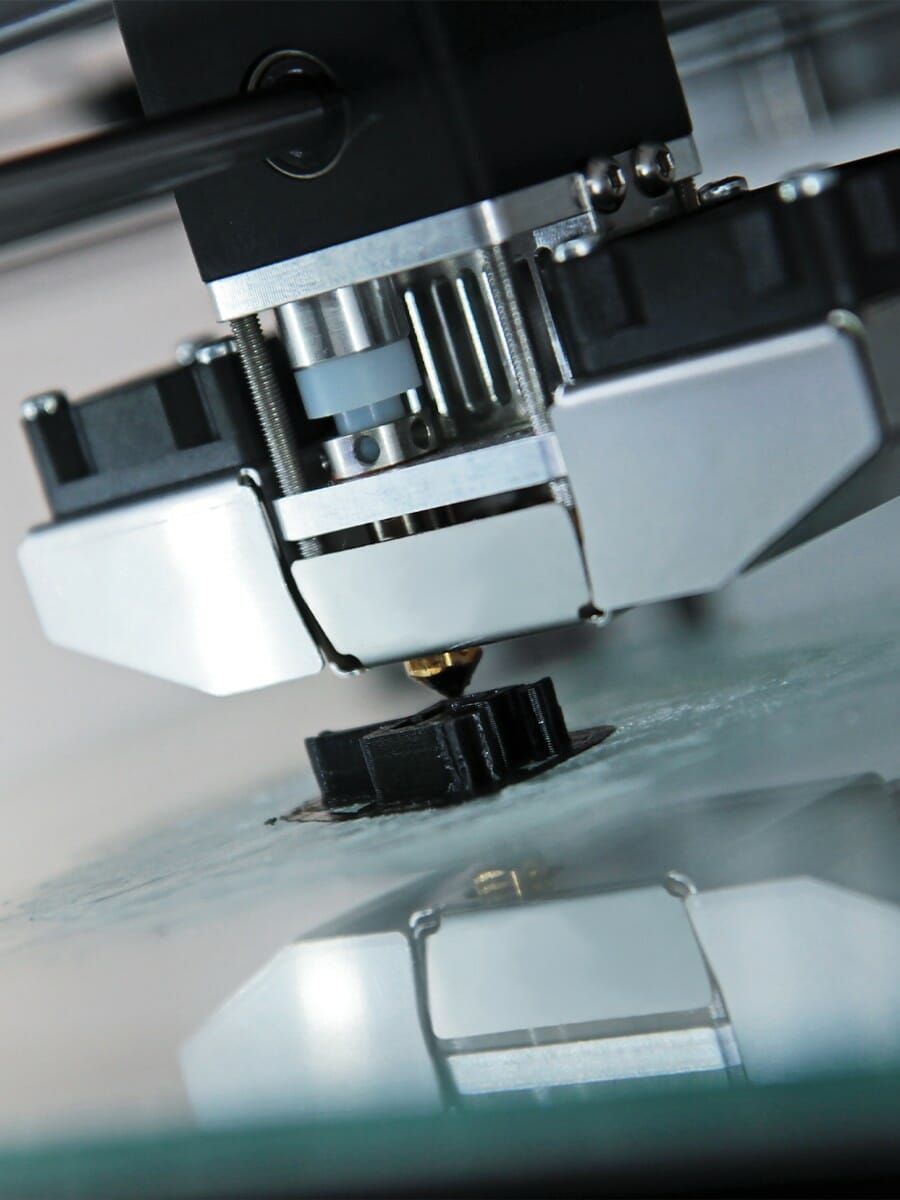

PROTOTYPING

Our proven system presents consistency for the customer from project to project.

– 3D electronic files (Native Solidworks, STEP and IGES file formats preferred)

- No automated quoting. A real person evaluates parts for moldability.

- Insert based system and parts within a 7.5” x 7.5” x 4.5” window for standard inserts (this footprint is growing)

-Molds typically constructed of high-grade aluminum and some steel components

- Side actions, complex part geometry, mold textures, insert molding and over molding supported

- No maintenance or mold storage charges

- Custom-sized dedicated bases are possible with extended lead times

Capabilities & Competencies

What our customers are saying about us

See what Westfall clients have to say about a variety of services that we provided for their projects.

Westfall possesses tremendous capability beyond their level of precision to include phenomenal client service.

These parts look incredible! We are so pleased with the first shots.

2025+

Qualified Associates

312+

Automated Machines

1M+

Manufacturing Space

18+

Worldwide Locations

Get in touch today

Want one of our Industry Experts to contact you to discuss your next project? Fill out the form to the right and we’ll contact you today!

Schedule a Strategy Session

Please complete the form below and we'll contact you to discuss a customized solution to fit your needs.