Westfall delivers integrated plastics solutions that

benefit both People and Planet.

We believe in the power of Plastics for Good, and design our products to save and improve millions of lives everyday while minimizing our carbon footprint and supporting the Circular Economy.

Environment

Protecting our planet

- Using our hot runner systems to reduce production scrap by up to 95%

- Reducing carbon footprint through stack molding capabilities to reduce energy by 50-60%

- Other energy efficiency projects include implementing LED lighting, reducing cycle times, and using solar panels

- Increasing the use of post-consumer recycled resin

- Continuously improving our environmental impact by setting and reviewing environmental objectives

Social

Delivering solutions for human well-being

- Bioabsorbable implantable tack for hernia mesh fixation

- Wearable injector systems for assisting in daily diabetes management

- Bioabsorbable bone screws containing TCP that can increase joint reconstruction healing time by 30%

- Annual Coastal Cleanup Event

Governance

Creating a culture of responsibility and results

- Built the Green Team to create company-wide engagement in sustainability initiatives

- Implemented a company-wide environmental policy

- Set emissions targets

- Comply with all applicable environmental laws, regulations, and guidelines

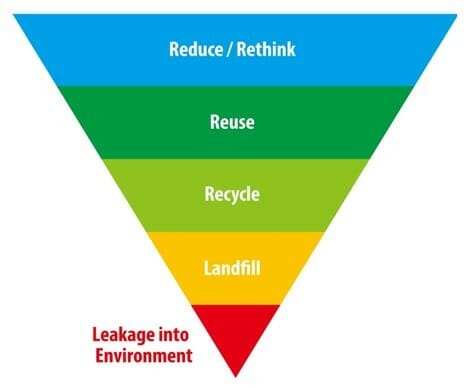

Our Sustainability Journey

We are working across the waste hierarchy to:

- Reduce problematic packaging and unnecessary plastic

- Drive reusable models

- Ensure packaging is recyclable, reusable, or compostable

- Increase recycled content levels

Reduce / Rethink

- Eliminate foil seals with proprietary closure technology

- Energy and cycle times reduction with advanced molding technologies, IVG nozzles, black box actuators, and MHS hot runners

- Design for right-weighting while maintaining structural integrity

- Reduce size of molds and steel consumption required with compact designs

- MHS Hot Runners and M3 machines reduce materials by 45-50%

Reuse

- rMolds enable molds to be re-used for program/product updates

- Reusable cups via EcoCore technology

Recycle

- Include up to 100% recycled content

- Design products for recyclability

- Proprietary closure technology to improve total product recyclability

- APR Demand Champions and Healthcare Plastics Recycling Council members

- Ellen MacArthur Pledge for a New Plastics Economy

- Leverage chemical recycling to drive Sustainability in Healthcare

Landfill

We are avoiding landfills by leveraging vision systems to re-use materials internally or partnering with brands to re-use scrap.

Leakage into the Enviroment

Operation Clean Sweep Certification to prevent resin leakage into water ways.

- Leveraging our proprietary closure technology, we are qualifying new designs with major beverage and food companies to remove from HDPE and PET bottles that will eliminate over 500,000 pounds of non-recyclable foil liners a year

- Our Design group is actively working with customers to light-weight their packaging, which would eliminate over 500,000lbs of resin a year

- We have implemented 46 MHS Hot Runners, which eliminates 162,000lbs of resin in runner scrap materials

- In partnership with major beverage and food brands, we have launched over 10,000 reusable cups and bowls, eliminating over 80,000 single use cups with plans to expand to over 1MM cups and bowls

- We regrind our scrap to reuse within our products and keep resin out of landfills

- Our design team is trained on the APR Guidelines for Designing for Recyclability

- We encourage customers to avoid mixing materials and to design products out of easily recyclable materials

- With our proprietary closure designs, we have transitioned fabric and home care closures from PP to HDPE (a widely accepted material in the recycling stream), contributing to ~2 million lbs of material being more widely recycled

- We have partnered with our customers to qualify parts that will use around ~1.5 million lbs of recycled content per year, with projects underway to utilize an additional 2 million lbs of recycled content per year

- We are part of the APR Demand Champion program to continually drive demand for recycled content

- Using technical molding principles, we have proven the ability to achieve 100% recycled content in multiple product applications

We are partnering with our customers, suppliers, competitors, and NGOs to drive sustainability and the circular economy. Our partners include:

- The Association of Plastic Recyclers, APR Recycling Demand Champion, Design Team is trained in the APR Guidelines for Designing or Recyclability

- The Ellen MacArthur Commitment for a New Plastics Economy

- Operation Clean Sweep Certified

- The Earth Charter Signatory

ESG Targets

- By 2035, we will reduce our Scope 1 and 2 greenhouse gas emissions by 63% compared to 2022.

- By 2050, we will reduce our Scope 1 and 2 greenhouse gas emissions by 100% compared to 2022.

- By 2030, 50% of the water used in industrial processes will be recycled and reused.

- By 2025, 50% of resin and additive suppliers will have signed the Supplier Code of Conduct.

- By 2025, all new and existing suppliers will sign the Westfall Technik Code of Conduct or supply their own that covers the same principles.

Documents

We want both publicly available documents and documents available by request, which we may decide to provide to our stakeholders. List documents. By clicking on a document, a pop up appears to submit a request. Pop up includes Name, Organization, Email, and Purpose for document request. Requests should be sent to [email protected].

Public documents: Environmental Policy, Supplier Code of Conduct, Environmental Report

Request documents: ESG Roadmap, CDP, EcoVadis

ESG Targets

- By 2035, we will reduce our Scope 1 and 2 greenhouse gas emissions by 63% compared to 2022.

- By 2050, we will reduce our Scope 1 and 2 greenhouse gas emissions by 100% compared to 2022.

- By 2030, 50% of the water used in industrial processes will be recycled and reused.

- By 2025, 50% of resin and additive suppliers will have signed the Supplier Code of Conduct.

- By 2025, all new and existing suppliers will sign the Westfall Technik Code of Conduct or supply their own that covers the same principles.

Documents

We want both publicly available documents and documents available by request, which we may decide to provide to our stakeholders. List documents. By clicking on a document, a pop up appears to submit a request. Pop up includes Name, Organization, Email, and Purpose for document request. Requests should be sent to [email protected].

Public documents: Environmental Policy, Supplier Code of Conduct, Environmental Report

Request documents: ESG Roadmap, CDP, EcoVadis

Sustainability News

2025+

Qualified Associates

312+

Automated Machines

1M+

Manufacturing Space

18+

Worldwide Locations

Sustainability is an ongoing journey, and we are committed to continuous improvement as we recognize the impact of our industry. We are embracing the opportunity to create a more sustainable world, and we are striving towards a future where plastics play a vital role in an environmentally conscious and circular economy. We are currently making strides to improve our third-party reporting, increase our energy efficiency, decrease our Scope 1, 2, and 3 greenhouse gas emissions, and promote circular materials.

Contact us to learn more about our sustainability initiatives.

Get in touch today

Want one of our Industry Experts to contact you to discuss your next project? Fill out the form to the right and we’ll contact you today!

Schedule a Strategy Session

Please complete the form below and we'll contact you to discuss a customized solution to fit your needs.